Man Machine Utilization Chart

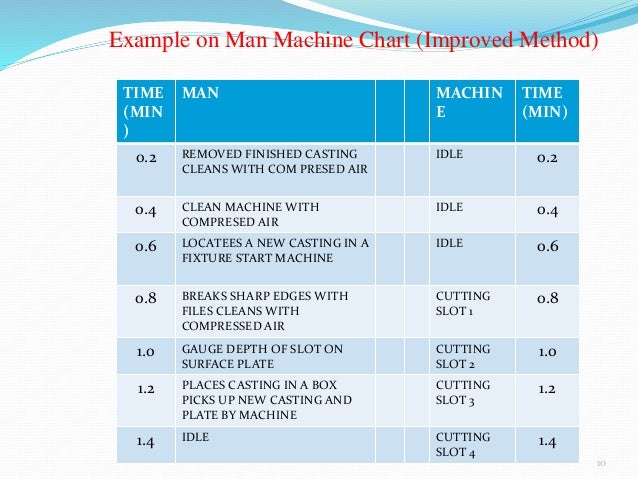

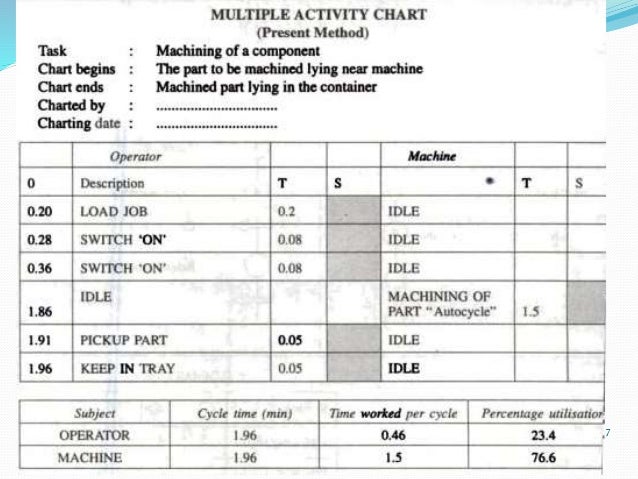

Identify independent combined and idle activities. Calculate utilization for man and machine.

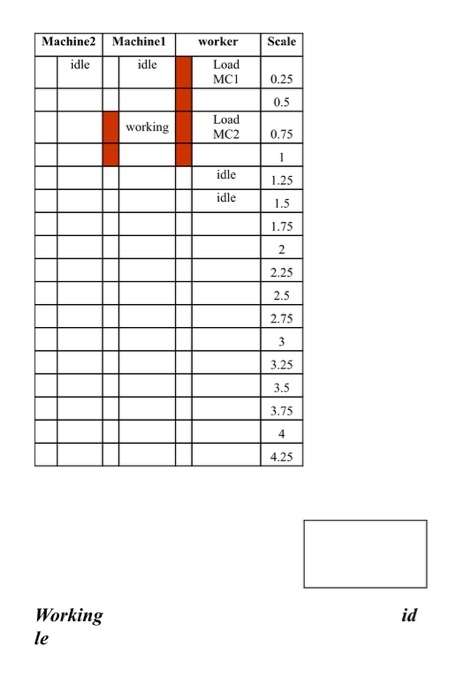

Complete the man-machine chart.

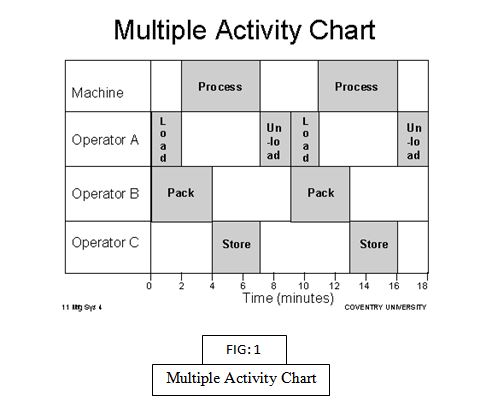

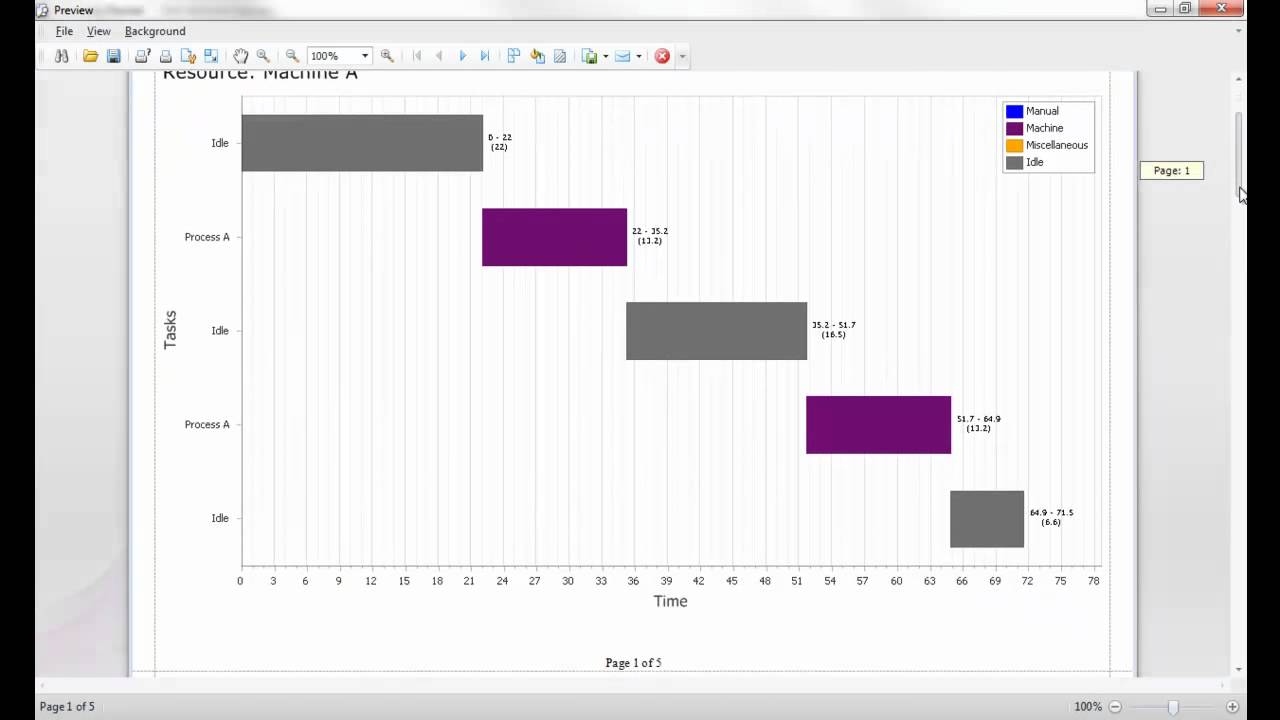

Man machine utilization chart. Using a Man and Machine Chart compute the Utilization of the 1 Man 2 Machine Al 3 Machine A2 4 Machine B1 The Operation starts when the Operator Loads Machine Al and ends when the Operator finishes unloading Machine B. Furthermore this tool called MUAT Machine Utilization Analysis Tool was developed as part of the production analysis tool set available on the CIM Com- puter Integrated Manufacturing system called CAFE Computer Aided Fabrication. In a system there are two machines.

Thus the new sequence reduces the idle time both for man and machines. They can easily highlight areas of inefficiencies. Construct man and machine chart.

1 Min and Inspection Time. Minmax date overlap. Timer Pros work balancing features allow you to quickly develop man-machine charts from any process as shown in.

45 Current labor utilization for inspector 31 46 Yarnazumi chart of floor console assembly line 32 47 Propose man to machine ratio for operator. Represent the sequence of operations and inspections by their symbols. After completing this experiment you will be able to.

The minutes for each company differ greatly even among highly profitable companies. Record the activities performed by the operator and machine. 130 employees 40 hours 5200 hours for the week.

Machine utilization time 22602260 x100 100. Represent the main component at the right extreme. Date based on wkday.

An example of worker-machine chart is shown below. However as the number of machines operated by MS increases it is more difficult to use the man-machine chart to comprehend the system complexity to fine tune manning ratio to improve MS or machine utilization Aft 2000. Connect them by vertical flow lines.

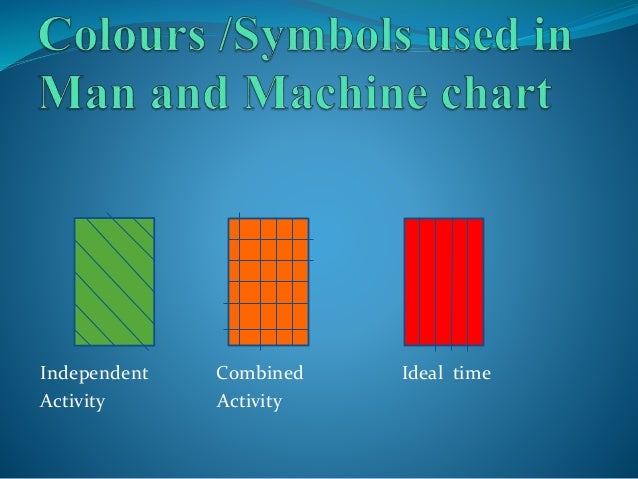

Make preliminary entries on the man-machine process chart. Man-machine charts allow engineers to visually compare the time that multiple machines and operators are occupied and working. Write title at the top of the chart.

A man-machine chart graphically represents the relationship between the manual work performed by one or more operators and one or more machines involved in a manufacturing process. Proplanners ProTime Estimation estimation generates man-machine charts based on time standards and processes that users established. And man utilization time 10802260 x 100 4779.

Numbers closest to sum. Utilization ratio of MS and machine. To study Prepare Man-Machine Multiple Activity Chart for the given situation OBJECTIVES.

60 machines with 2040 HMR 5200 60 235 minutes. No net close to zero. Find numbers in sum.

Analyze the chart to eliminate non value adding activities. 9 Min Unloading Time. MACHINE A ACTIVITY LOAD INSPECT TRAVEL MACHINING UNLOAD TIME MIN 1 05 05 7 1 MACHINE B ACTIVITY LOAD INSPECT TRAVEL MACHINING UNLOAD.

In short Man-Machine Process Chart helps us to increase percentage utilization of man and machine. To use the man-machine chart as a guide to introduce improvements in work methods that utilize both man and machine. Man and Machine Chart Description of the Activity of Man Description of the Activity of Machine- I Loading Machine- I Idle.

Worker and Machine Process Chart The worker and machine process chart is used to study analyze and improve one workstation at a time. Study the given situation and break up the job into different activities of man and machine. D and operator I 33 48 Propose labor utilization for operator D and Tin floor console 34 assembly line 49 Labor utilization for operator D 35 410 Labor utilization for operator 1 36 xii.

Begin the chart from the right hand side top corner. Record the activities performed by the operator and machine. Construct man and machine chart.

Calculate utilization for worker and machine. Therefore this chart is used to establish man-machine ratio and to minimize idle MSmachine time to optimize resources of MS and ma-chines. Draw a Proposed Man and Machine Chart for a Job with the following data in order to enhance the Utilization of a man and two machines.

Procedure Followed In Preparing The Chart 1. Record the activities being performed by the man and machine during cycle using common time scale. Find numbers in sum.

The activity chart can be drawn on the same lines as for Example 1. The minutes calculation is best used as an internal labor and machine productivity tool. Objective After completing this activity students will be able to 1.

2 Min Machining Time.

Download Our Capacity Planning Tool Version 2 0 Production Scheduling

Knowledge Management Lifecycle Knowledge Management Knowledge Knowledge Management System

Metric Tap Clearance Drill Chart Png 1642 1927 Drill Bit Sizes Metric Thread Chart Drill

Process Strip Layout Design In Progressive Stamping Layout Design Progress Design

Check Out This Amazing Template To Make Your Presentations Look Awesome At Powerpoint Templates Gantt Chart Powerpoint Presentation Slides

Man Machine Chart Multiple Activity Chart Multiple Activity Chart Hindi Youtube

Process Flow Chart For 100 Polyester Dyeing In 2021 Process Flow Chart Process Flow Flow Chart

Solved Case Studydraw A Man Machine Chart Showing One Chegg Com

Capacity Management Google Search Management Capacity The Unit

Interview Question For Sr Executive Ie Or Work Study Officer Textile Study 365 This Or That Questions Interview Questions Interview

Man Machine Chart Multiple Activity Chart Multiple Activity Chart Hindi Youtube

Multiple Activity Chart Toh Problem Kya Hai

Post a Comment for "Man Machine Utilization Chart"