Machine Utilization Definition In Engineering

Utilization is fundamentally a percentage-based metric eg our current utilization is 4762. From a discrete manufacturing perspective we can define utilization as the proportion of time that manufacturing equipment is used.

Artificial Intelligence Images Artificialintelligence In 2020 Artificial Intelligence Technology Machine Learning Artificial Neural Network

Machine utilization can be expressed as a percentage for example.

Machine utilization definition in engineering. Key factor that keeps the machine running efficiently through the production process. OBJECTIVES By Definition machine to the To determine the utilization of machines and overall equipment effectiveness of machine shop by analyzing the data obtained. Initially a focus on determining a percentage of machine utilization can be made which compares actual production time with planned production time.

Utilization can be defined as how much something is used. Few people advocate using human labor to do work that can be done better and cheaper by machines. A manufacturing process that has been thoroughly optimized via lean can work against cash management when measured by machine utilization and allowed to produce oversized batehes.

The APICS Amer-ican Production and Inventory Control Society Dictionary 9. How do you calculate. Reflect forecasted quantity in comparison to maximum capacity.

More complex and rigorous Reliability and Maintainability Engineering analyses exist. In a real world scenario there are other factors that one need to consider when plotting the capacity chart. To determine the utilization of machines and overall equipment effectiveness of machine shop by analyzing the data obtained.

Machine Utilization Principle of Industrial Engineering - Prof. It could be a single machine or a complete facility. Manufacturing efficiency can often be greatly improved by identifying the real reasons and true extent of production stoppages constraints or bottlenecks caused by machine.

2002 2005 C Pass B Lowes A Pendleton L Chadwick D OReilly and M Afferson. METHODOLOGY machine has produced. Machine Downtime Machine Utilization and Downtime Systems.

Machine utilization the extent to which the productive capacity of a machine is used during a specified period of time. Capacity utilization or capacity utilisation is the extent to which a firm or nation employs its installed productive capacity. Find out more at the dedicated PlantRun website.

The evaluation of the method of lot size determination in manufacturing system. Equipment utilization sometimes referred to as asset utilization is a measurement of the use and performance of site machinery which assists businesses to improve jobsite productivity and reduce the cost of equipment rental and project delays. Machine Utilization rates.

It is Time a resource usedTime a resource availableIf let say a machine can be used up to 30 hours but we are only using only 28 hours of it then Machine Utilization 2830 093Hope this can help you. The maintenance activity on machines needs extra attention by the management along with the responsible personnel to ensure optimum usage of machineries which will eliminate unwanted wastages due to machine stoppages. Parts produced on the machine.

Optimum Utilization of Machine means to use a Machine in such a way that we produce at the maximum capacity after spending its In Short Higher Productivity in low Cost. It is the relationship between output that is produced with the installed equipment and the potential output which could be produced with it if capacity was fully usedThe Formula is the actual output per period all over full capacity per period expressed as a percentage. To determine the present condition of capacity utilization of machines and reasons for less OEE.

0 Viewing 4 posts - 1 through 4 of 4 total. To determine the present condition of capacity utilization of machines and reasons for less OEE. PlantRun OEE machine downtime and manufacturing information systems give manufacturers the accurate live production performance data needed to maximise efficiency output and profits.

A Machine Utilization Analysis Tool by Johnson Cheah-Shin Tan Submitted to the Department of Electrical Engineering and Computer Science in partial fulfillment of the requirements for the degrees of. Identification of manufacturing units. Generally genba your line often to understand their challenges.

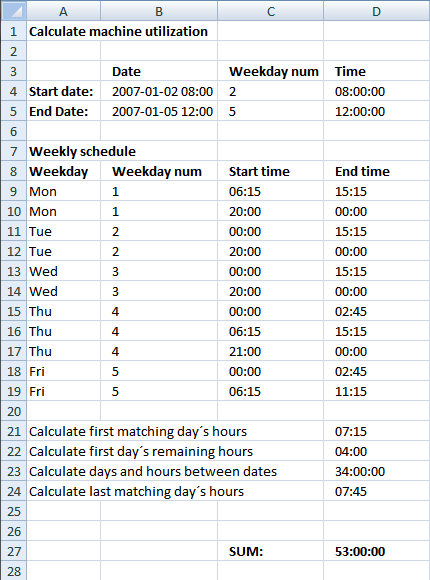

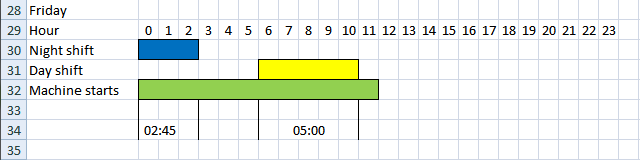

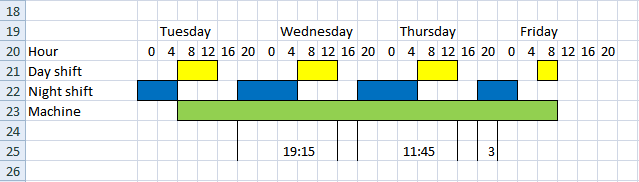

Using data obtained visualize it in beautiful graphing tools available in Excel. Collins Dictionary of Business 3rd ed. An OEE system can be implemented in a phased and scalable way.

We now develop a more quantitative definition of capacity. The term is applied to a piece of manufacturing equipment acting as a unitusually one machine but several machines if they produce as a unit and can consider all supporting elements. From this simple measurement.

Collection of data and codification of activities.

Capacity Utilization Manufacturing Kpi Examples Sisense

Capacity Utilization Rate Formula Calculation With Examples Youtube

Osha Definition Of Hot Tap And Normal Production Operations Lockout Tagout Employee Training Osha

Hire Machine Learning Engineer And Data Scientist For Ai Models Development Data Scientist Machine Learning Scientist

Jit Just In Time Manufacturing Cesar Monzon The Pin Explains Details And Examples Of Just In Time Manu Just In Time Manufacturing Business Studies Elearning

Services Pulses Dal Milling Sesame Seed Processing Rice Mill Rice Plant Milling

12 Useful Formulas For Industrial Engineers Poster Industrial Engineering Garment Manufacturing Engineering

Calculate Teep Measure Utilization And Capacity Oee

What Is Utilization Definition And Example Market Business News

Learning Experience Platform Lxp Market Grows Up Now Too Big To Ignore Josh Bersin Learning Learning Management System Ways Of Learning

Utility Matrix Utilization For Manufacturing Processes

Osha 1910 147 C 2 Lockout Tagout Lockout Tagout Lockout Osha

Warehouse Kpis And Balanced Scorecard Warehouse Management Business Strategy Business Intelligence

Calculate Teep Measure Utilization And Capacity Oee

Internet Of Everything Depicts Crucial Aspects Of Iot People Data Things Processes Cloud Computing Services Internet Marketing Strategy Google Technology

Post a Comment for "Machine Utilization Definition In Engineering"